Natural Granite - No Colorants

Base Glaze Experiments

The following documents tests and results using the Mt Vision Granodiorite without colorants.

Glaze Recipe

This calcium flux dominate glaze produces a matte, semi-clear to gold color. The variations are due to the iron content of the granite and the amount of micas in the glaze, both of which can change from batch-to-batch.

Sieving at 120M removes much of the micas and produces a more creamy glaze. A serviceable glaze can be achieved without the addition of silica. The addition of zinc instead of silica will produce a glossy version.

Mt Vision Gold

| Material | Amount |

|---|---|

| Mt Vision Granodiorite | 64% |

| Wollastonite | 27% |

| Silica | 9% |

| 100% | |

| Bentonite | 2% |

| 102% |

The chemical makeup of the Mt Vision Granodiorite is described here.

Firing

Kiln firing procedures are described here.

Discussion

Tests

The following documents "base glaze" testing with the granite and its associated local (primary) clay. Performed closely in parallel are the Iron Oxide (Tenmoku) tests, as well as the Cobalt and Copper testing.

Test Synopsis

TODO

Test 10

Date:04/23/24

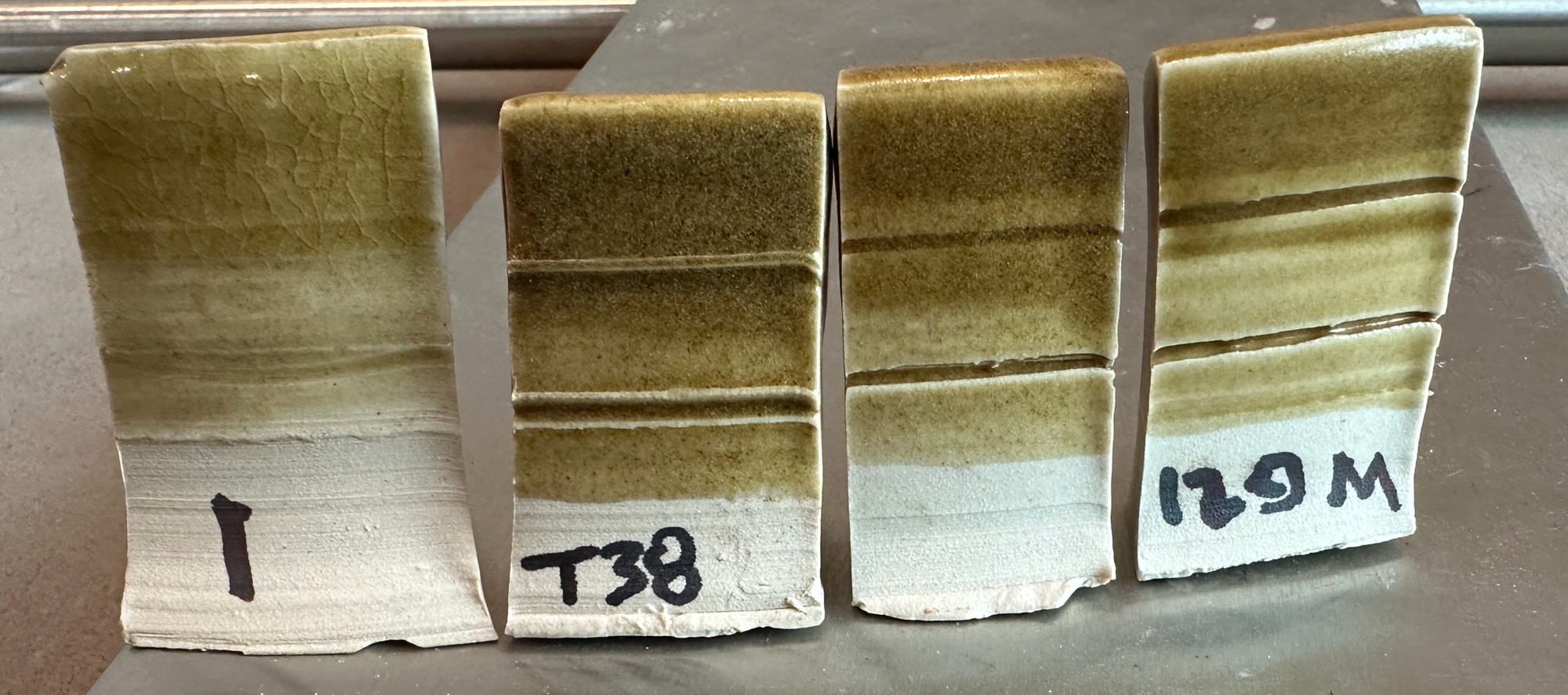

Type: Sieving comparison

Temp: Cone 6

Kiln: Test Kiln (T28, T38), Main Kiln (G46)

Clay: B-Mix

Method: Comparing 60M, 80M and 120M using a new 3000 gm batch of granodiorite. Benchmarked with an earlier glaze test at 60M.

Recipe is 70/30/10% MVG / Wollastonite / Silica + 2% Bentonite. SG 1.45

What instagated the test is this glaze batch came from recent milling that contains a lot more mica than the benchmark tile, as shown below, and as a consequence came out much darker (it's all MV Granodiorite witout any MV Granite, which initial milling batches contained).

Notes

We see, progressing left to right:

- An early 70/30% MV Granodiorite-Granite / Wollastonite glaze batch, which is glassy and crazing, on B-Mix (Tile 1).

- A recent 70/30/10% MV Granodiorite / Wollastonite / Silica version sieved at 60M, 80M and 120M, which are more matte and darker, on B-Mix (Tiles 2-4).

The comparison shows:

- The new batch is darker due to more mica and perhaps more iron. Recent milling has only granodiorite in them, which trends more mica-rich.

- Sieiving the micas out progressively from the recent glaze move the color towards the early glaze benchmark, but not completely, as there also is more iron in the granodiorite.

- The earlier batch had a better flux balance to achieve a glossy finish than when more mica (and iron) is present. The three tiles from the mica-rich batch are all matte, though there is a slight improvement in the melt from 60M to 120M.

Test 9

Date:01/25/24

Type: Line Blend

Temp: Cone 6

Kiln: Main Kiln (GXX)

Clay: B-Mix

Method: Testing progressivly adding EPK to the 70%/30% Granite / Wollastonite base glaze using milled granodiorite (not mixed granite / granodiorite). Added 0, 2.5gm, 2.5gm, 5gm and 5gm to 100gm of material + 125 ml water, so 2.5%, 5%, 10% and 15%.

Notes

TODO - obtain picture

This was a dud test

Test 8

Date:01/25/24

Type: Line Blend

Temp: Cone 6

Kiln: Main Kiln (GXX)

Clay: B-Mix

Method: Testing progressivly adding Boron, via Frit 3134 to the 70%/30% Granite / Wollastonite base glaze using milled granodiorite (not mixed granite / granodiorite). Added 0, 2.5gm, 2.5gm, 5gm and 5gm to 100gm of material + 125 ml water, so 2.5%, 5%, 10% and 15%. Hoping to cause a melting!

Notes

TODO - obtain picture

No melting!

Test 7

Date:01/04/24

Type: Test Tiles

Temp: Cone 6

Kiln: Test Kiln (T31)

Clay: B-Mix, Red Sedona

Method: A straight comparison of "Tile #22 in Tenmoku Test 7", more Silica.

The Tile #22 formula is 67% Granodiorite, 29% Wollastonite, 4% Silica with 2% Bentonite added.

Chemically this is a 1:10.3 aliumina / silca ratio with 0.77% Calcium and 0.18% K-Na

I added this just to complete the T31 suite of Base, Tenmoku and Cobalt tests. It's too early to say the added Silica is an improvement though there it seems so. It also (re)confirms the base glaze looks nice on the Sedona Red, a warm honey. And no crazing!

Test 6

Date:12/8/23

Type: Biaxial 5x5 Blend Tests

Temp: Cone 6

Kiln: Main Kiln (G37)

Clay: B-Mix

Method: Each corner glaze contained 300 gm of material and 500 ml of water. The flux corner C was 70% Granite and 30% Wollastonite, the current base receipe. 20 gm of Silica was added to corners B and D and 15 gm of EPK (alumia) was added to corners A and B.

The resulting corner recepies were

| A | B | C | D | |

|---|---|---|---|---|

| Granite | 183 | 156 | 210 | 174 |

| Wollastonite | 78 | 66 | 90 | 75 |

| Silica | 0 | 45 | 0 | 51 |

| EPK | 39 | 33 | 0 | 0 |

| 300 | 300 | 300 | 300 |

I applied the resulting blends to 2 5x5 flat tests and 1 set of 25 self standing test tiles. One flat tile was placed at the bottom of the kiln were it usually cooler and the other flat tile and the self standing tiles were placed at the top of the kiln.

I meant to add 420 ml of water, so the corner glazes were more watery than indended and had an SG ~1.35.

Notes:

-

According to the kiln cones, the top of the kiln fired to 35-40% Cone 7 while the bottom fired to 25% Cone 7, with Cone 6 surpassed. So hot, if Cone 6 is the target. This has been my normal firing schedule for some time. This time the temperature differential between the top and the bottom of the kiln is pretty small. This is not always so, but it is always within a cone.

-

The flat tiles are not providing much information, everything seems underfired (perhaps because I blew it and added too much water to the corner receipies?). The one located at the bottom of the kiln (lower left) is slightly less well fired than the one from the upper portion (upper left). What is strange or noteworthy is all other pieces in the kiln with the granite (there were 5 bowls and a pitcher) were well fired and beautiful. Based, then, on the other pieces, the temperature differential in the kiln was negligable; one data point I was seeking.

-

Fortunately the self standing tiles do illuminate the eutectic mapping sought after. Observationally, in terms of a glossy (fully melted) target, the "best" tiles are #11 and perhaps #12.

Very roughly this empirical mapping below can be gleaned from the tiles.

| A | matte | matte | glossy | glossy | underfired | B |

| matte | GlOSSY | GlOSSY | underfired | underfired | ||

| GLOSSY | GLOSSY | semi glossy | underfired | underfired | ||

| semi glossy | semi glossy | semi glossy | underfired | underfired | ||

| C | semi glossy | semi glossy | semi glossy | underfired | underfired | D |

If we look at A, B, C and D in terms of their Silica to Alumina distributions we find

| A | B | C | D | |

|---|---|---|---|---|

| Silica | 3.09 | 3.97 | 2.80 | 3.68 |

| Alumina | 0.43 | 0.43 | 0.28 | 0.28 |

| Ratio | 1:7.2 | 1:9.2 | 1:10.0 | 1:13.1 |

A ratio of 1:8 is considered the target for a fully-melted, glossy glaze at Cone 10, per Ian Currie. Given the data above one would expect the 1:8 zone to run diagonally between corners A and C and A and B, which in fact they do seem to do.

Using glazy.org to calculate the alumina / silica ratios for the entire grid we get

| A | 1:7.2 | 1:7.6 | 1:8.2 | 1:8.6 | 1:9.2 | B |

| 1:7.7 | 1:8.3 | 1:8.8 | 1:9.4 | 1:10.0 | ||

| 1:8.2 | 1:8.9 | 1:9.5 | 1:10.1 | 1:10.8 | ||

| 1:9.1 | 1:9.7 | 1:10.3 | 1:10.9 | 1:11.9 | ||

| C | 1:10 | 1:10.5 | 1:11.4 | 1:12.1 | 1:13.1 | D |

So the science seems to be working here!

Next steps appear to be:

-

Test with Tile #11 which has a glaze recipe of 66% Granite, 28% Wollastoneite and 7% EPK. Note: I did this in Tenmoku Test 6 and the results were not as expected and disappointing. With iron oxide more clay is not helping, but it seemed to with the base glaze.

-

Try swapping out the EPK for the Mt Vision Clay.

-

Perform this test again but blow up the map by selecting 10 gm of Silica instead of 20 and 10 gm of EPK instead of 15.

-

Make Tile #11, having an 1:8 ratio the corner glaze C

A final note, I've had good success to date with the Corner C glaze and so I find these results quite encouraging.

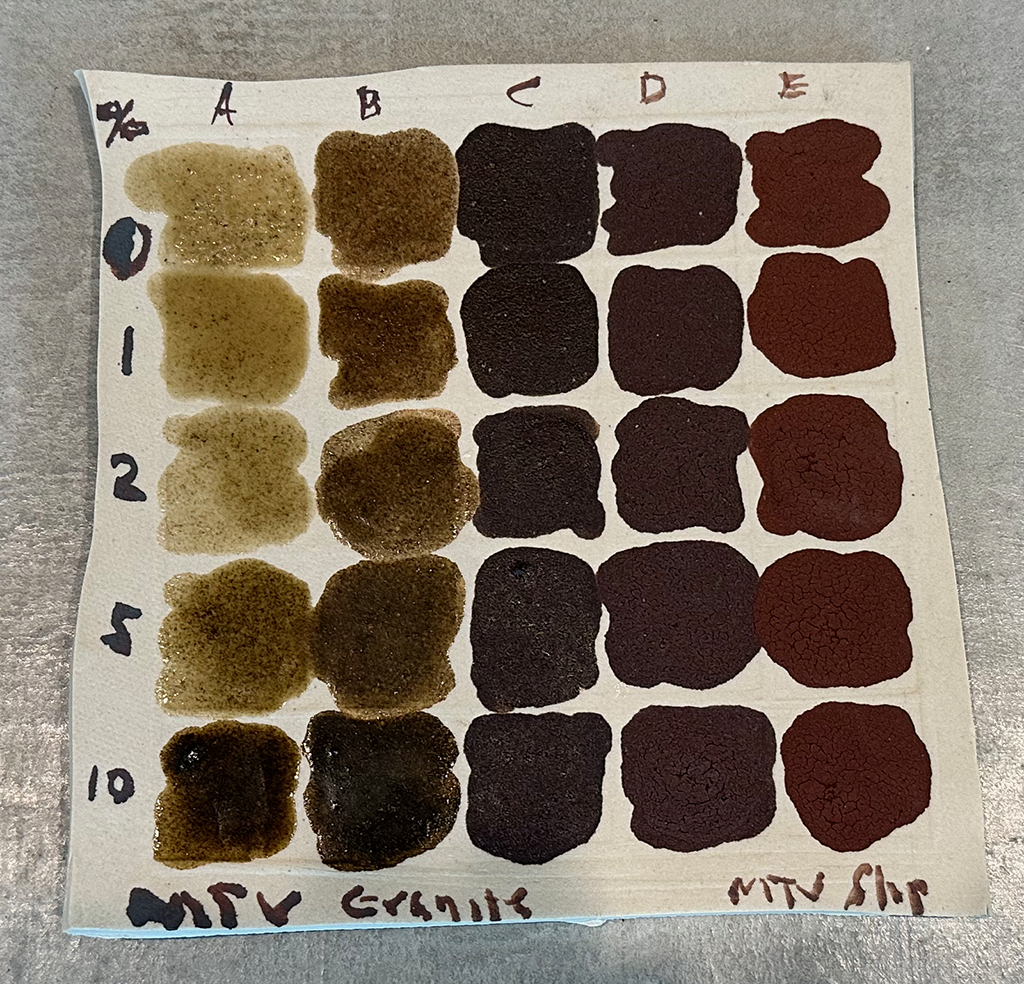

Test 5

Date:4/29/23

Type: "2D" Line Blend

Temp: Cone 6

Kiln: Test Kiln (T23)

Clay: B-Mix

Glaze A: 75% / 25% Mt. Vision Granite (12hrs milling / 60M seive) / Wollastonite

Glaze B: Mt Vision Slip

Additive: Red Iron Oxide

Method: Essentially ran a line blend using iron oxide for each of the five samples.

Notes:

| A | B | ||||

|---|---|---|---|---|---|

| 100 | 75/25 | 50/50 | 25/75 | 100 | |

| +FeO2 | 1 | 2 | 3 | 4 | 5 |

| 0g | Somewhat melted, like other tests | Melted but matte, darker due to slip | Not melted, dark | Not melted, medium dark | Not melted, red |

| 1g | Melted | Melted but matte, darker due to slip | Not melted, dark | Not melted, medium dark | Not melted, red |

| 2g | Melted | Melted but matte, darker due to slip | Not melted, dark | Not melted, medium dark | Not melted, red |

| 5g | Melted | Melted but matte, darker due to slip | Not melted, dark | Not melted, red | |

| 10g | Tenmoku here | Tenmoku here | Not melted, dark | Not melted, medium dark | Not melted, red |

Conclusions:

1 and 2 show promise but are missing something. Perhaps there is not enough Silica. But if these two Mt Vision materials items are to work together we need more Silica and probably something else. It would help to have the slip analyzied like performed for the granite.

Afterthought - I put this testing aside for a bit and plan to come back to it later. It would be fun to combine them at some point.

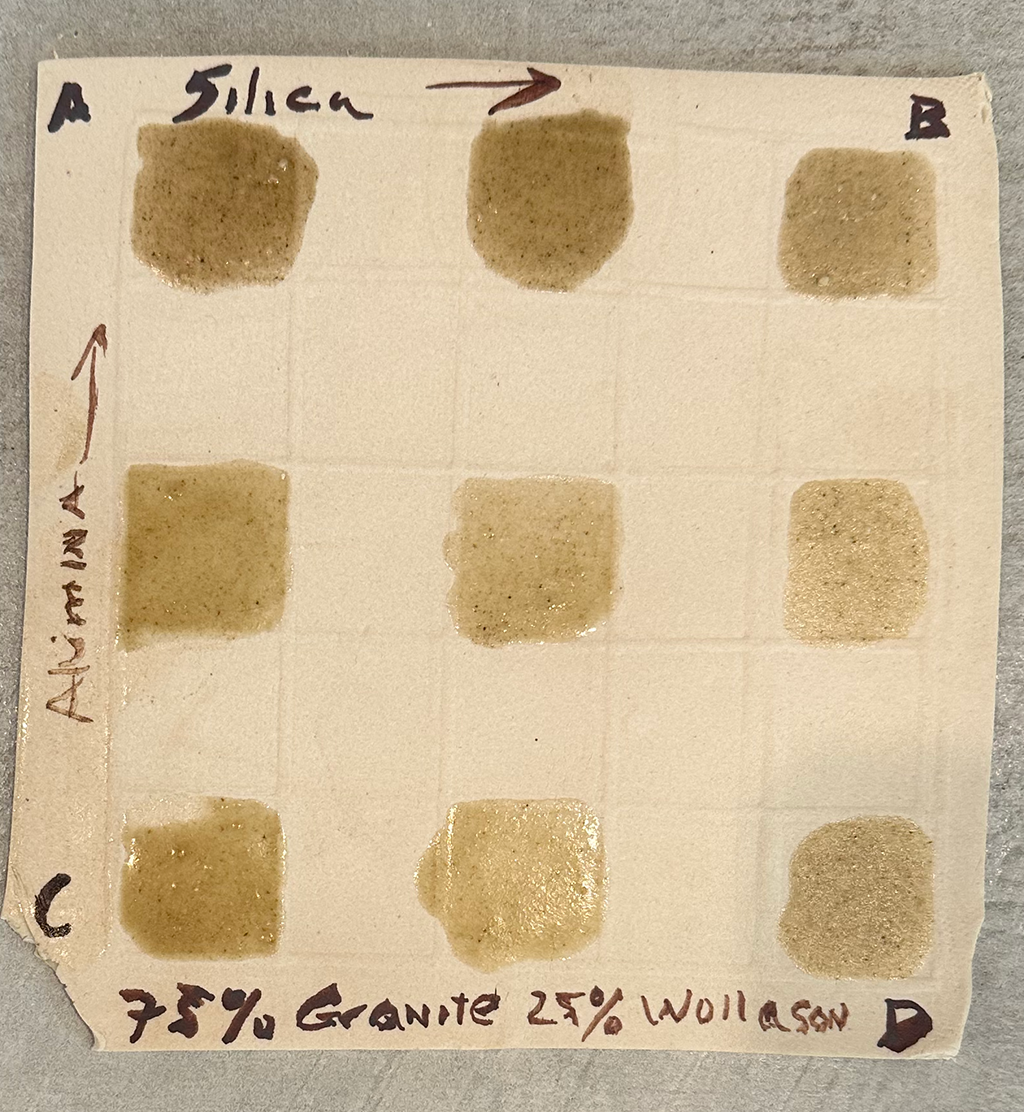

Test 4

Date:4/18/23

Type: Ian Currie Quick 9 Blend

Temp: Cone 6

Kiln: Test Kiln (T22)

Clay: B-Mix

Sample Size: A, B, C, D 100gm w/150mg water each

The Mt Vision Granite (MVG) is 75% granite (milled 12 hours / 60M seive) and 25% Wollastonite.

The corner recipies are:

| A | B | C | D | |

|---|---|---|---|---|

| MVG | 77 | 60 | 90 | 70 |

| EPK | 15 | 10 | 0 | 0 |

| Wollastonite | 8 | 5 | 10 | 7 |

| Silica | 0 | 25 | 0 | 23 |

Notes:

| A: Starting to move to matte | A+B: Slightly better than A in terms of melt | B: Too much silica, it did not melt |

| A+C: This is the best tile, nicely melted | A+B+C+D: Also good, but not as melted as A+C | B+D: Too much silica, it did not melt |

| C: This can work as a glaze itself | C+D: Also good, but not as melted | D: Too much silica, it did not melt |

Conclusions:

Encouraging results. As indicated by the prior Test 2, corner C is pretty good as it is, a little more alumina and flux is better as is observed in A+C.

Test 3

Date:3/25/23

Type: Line Blend

Temp: Cone 6

Kiln: Test Kiln

Clay: B-Mix, Dark Red

Glaze A: 50% / 50% Mt. Vision Granite (8hrs milling / 80M seive) / Wollastonite

Glaze B: Mt Vision Slip

Additive: Red Iron Oxide

Method: Run the prior line blend (test 2) adding iron oxide in the proportions listed below

| A | B | |||

|---|---|---|---|---|

| 100 | 75/25 | 50/50 | 25/75 | 100 |

| 0g | +10g | +20g | +10g | +10g |

Notes:

This is not a very accurate test, I had some extra material and so I am fishing for a Tenmoku.

1 – Good, more like a glaze

2 – Moving towards a Tenmoku, but matt, not fully melted, better on the red clay

3 – This looks like a Tenmoku! A bit on the runny side but didn’t stick to the test tile. Breaks nicely, real promise here.

4 – Also interesting, a dark chocolate or black. Approaching matt or metallic, not running

5 – Even more matt and not interesting as the others.

Conclusions:

As mentioned, this is a rough test. That said the 3rd tiles, with even mixture of granite/wollastonite and slip plus ~20g of iron oxide, produces a slightly runny, glossy Tenmoku with no visible crazing. Nice. As we started with 200g of material, the 20g of iron oxide would be between 10% and 20%?

Tile 4 has 25% A and 75% B plus 10g iron oxide. Given the slip has iron as well, but how much we don’t know, there is a lot of iron in this mix. But could also be another interesting area of exploration.

Afterthought - my notes are not very good and somewhat confusing and so I am discounting this test, but we did achieve a melted glaze and that's a good data point.

Test 2

Date:3/24/23

Type: Line Blend

Temp: Cone 6

Kiln: Test Kiln

Clay: B-Mix, Dark Red

Glaze A: Mt. Vision Granite (8hrs milling / 80M seive) 50%, Wollastonite 50% + 150ml water

Glaze B: Mt Vision Slip 100%, not measured well, took 4 tbls of 60M slip and added water until I reached 150m, same as Glaze A

| A | B | |||

|---|---|---|---|---|

| 100 | 75/25 | 50/50 | 25/75 | 100 |

Notes:

I will cover the slip in another blog post, but in a nutshell, it's primary clay from the property derived from the decomposed granite. I don't know its chemical makeup except that it's not very plastic and contains a lot of iron. As you can already see, it's going to be another fun place to play.

Reading over Hamish Jackson’s postings I observed his best acting flux was Wollastonite and that his Celedon and Tenmoku glazes used 20% Wollastonite at Cone 10. So, I went for 50% to see what would happen at Cone 6.

1 – Produced a matt glaze, but melted, or partially so.

2 – This ended up being the sweet spot producing a melted and translucent glaze approaching a celadon on the red clay. The B-mix is perhaps less interesting being a dirty brown, but it’s a glaze.

3 – Same results except we seem to be moving back towards a matt surface

4 – 4 is like 3 except more matt and less melted

5 – This looks like all the tests of slip being a bright iron matt finish that is not melted at all.

Conclusions:

Adding the 50% Wollastonite and 25% slip (iron clay) brought the eutectic into melting territory. This is an incouraging result.

Test 1

Date:3/21/23

Type: Line Blend

Temp: Cone 6

Kiln: Test Kiln

Clay: B-Mix, Dark Red

Glaze A: Mt. Vision Granite 100% (5hrs milling / 40M seive) + 175ml water

Glaze B: Whiting 100% + 175ml water

| A | B | |||

|---|---|---|---|---|

| 100 | 75/25 | 50/50 | 25/75 | 100 |

Notes:

1 – Granite appears to need more milling, not really a glaze, started to melt but did not

2 – Not well mixed, kind of melted, shows iron

3 – Better mixed, starting to melt, shows iron

4 – Gray, flaking, not melted, bland

5 – White, not melted

Conclusions:

Overall inconclusive, not much to learn except nothing is melting and the granite needs more milling

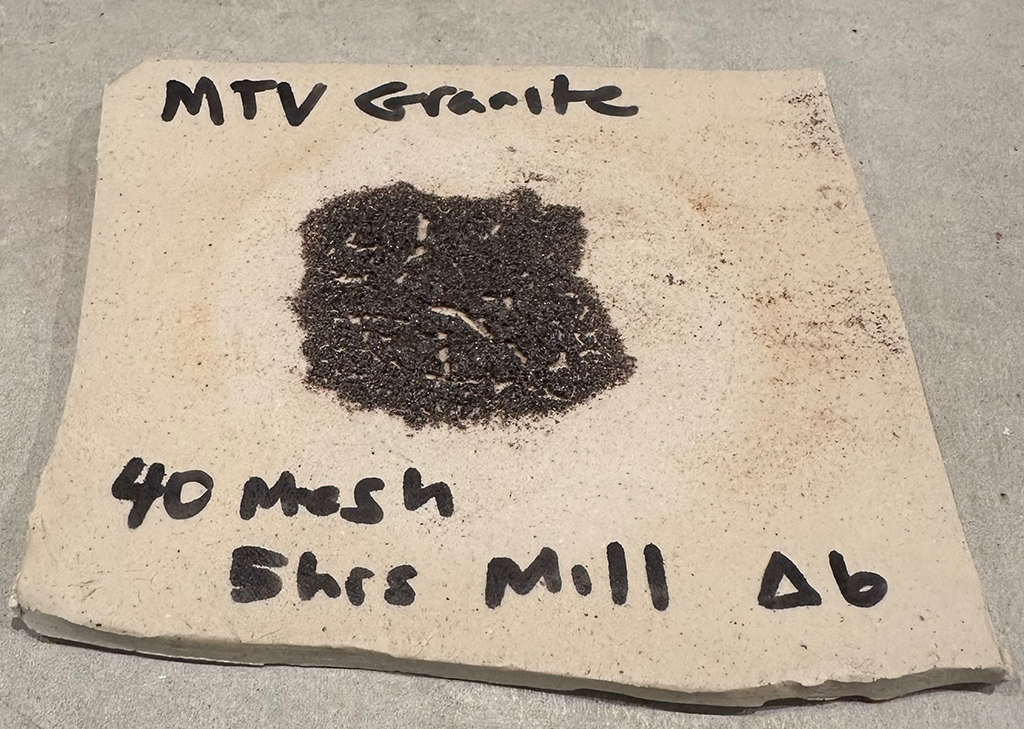

Test 0

For the record, the initial test to see what happens. Mt Vision Granite (5 hrs milling, 40M seive) with nothing added fired to Cone 6.