Updated Granite Glaze Map

An organized review combined with new granite glaze formulations!

Much ground has been covered over the past two years. Below is an attempt to organize and review recent and prior foundational glaze test results in a format that supports easier tracking, comparisons (and planning).

As such, some of the results below have been presented before and while others are fresh out of the kiln! After a lengthy period of process directed testing we are finally grounded enough to begin branching out again into new territory!

Single Glaze Tests

Base Glaze A

| Matrial | Percentage(%) |

|---|---|

| Mt. Vision Granite | 70% |

| Wollastonite | 30% |

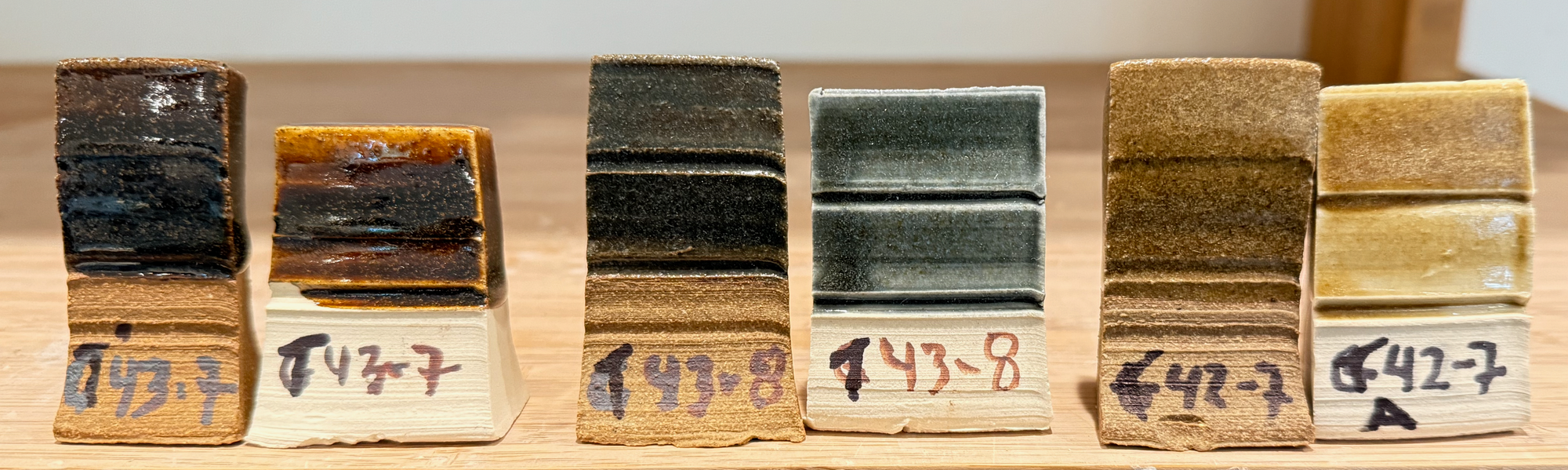

Base A produces a satin matte, semi-opaque glaze for No Colorant and Cobalt Carbonate versions, and a glossy, semi-opaque glaze with Red Iron Oxide.

For matte glazes, Base B is used more often now than Base A, but Base A is important being the first studio formulation with the granite.

Note, some early batches of milled granite produced glossy glazes instead of matte with this simple formulation. But Granite Batch A (the first large batch produced), which we are using now, produces matte.

| Base A | No Colorant | Iron | Cobalt |

|---|---|---|---|

| No Colorant | G42-7 | ||

| Iron | T43-7 | ||

| Cobalt | T44-4 | T43-8 |

Cobalt and Iron turn Green! This happened on its own using only Cobalt Carbonate with some early batches of milled granite that were, as we know now, more iron rich than others. With Granite Batch A, we need Cobalt and Iron to produce a green.

Base Blaze B

| Matrial | Percentage % | Normalized % |

|---|---|---|

| Mt. Vision Granite | 70 | 64 |

| Wollastonite | 30 | 27 |

| Silica | 10 | 9 |

Base B also produces a satin matte, semi-opaque glaze for No Colorant and Cobalt Carbonate versions and a glossy, semi-opaque with Red Iron Oxide. This is a favored formulation for matte versions of the granite glaze.

The Red Iron Oxide version (8-10%), which is glossy, not matte, we call Mt. Vision Tenmoku.

| Base B | No Colorant | Iron | Cobalt |

|---|---|---|---|

| No Colorant | G42-6 | ||

| Iron | T43-5 (Tenmoku) | ||

| Cobalt | T44-3 | T43-6 |

Base Glaze C

| Matrial | Percentage % | Normalized % |

|---|---|---|

| Mt. Vision Granite | 70 | 67 |

| Wollastonite | 30 | 29 |

| Zinc Oxide | 4 | 4 |

Base C produces a glassy, transparent glaze. Zinc Oxide is necessary to move from matte to glossy for the Non Colorant and Cobalt Carbonate versions. The Red Iron Oxide version starts to run in the presence of zinc and is not necessarily needed. The extra flux does help the micas in the granite to melt.

| Base C | No Colorant | Iron | Cobalt |

|---|---|---|---|

| No Colorant | G42-5 | ||

| Iron | T43-3 | ||

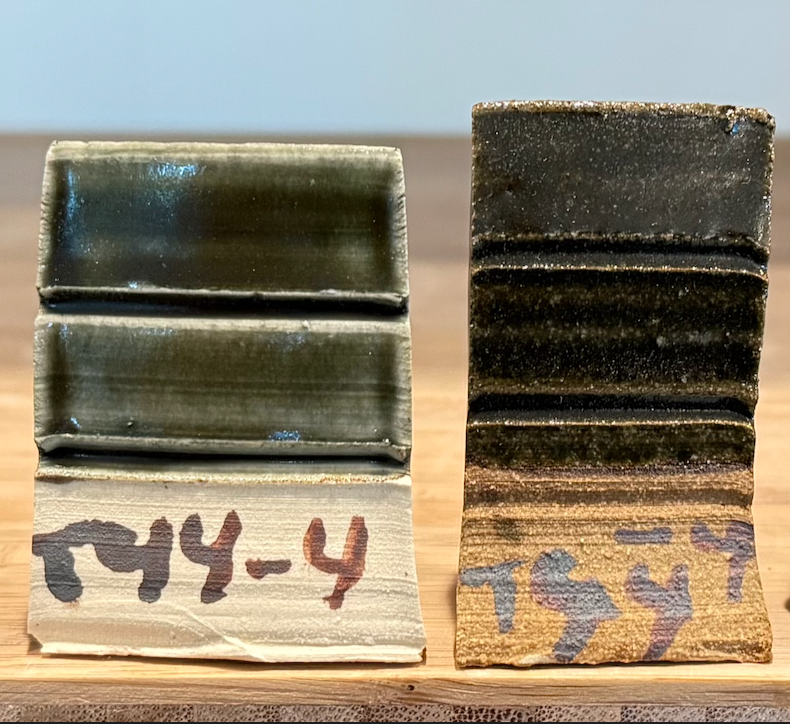

| Cobalt | T44-2 | T43-4 |

The glossy green "Celadon" produced in this formulation is quite attractive !

Base Glaze D is Base Glaze C (the Zinc Oxide formulation) + 1% Cobalt Carbonate.

Typically 0.25% or 0.5% Cobalt Carbonate has been selected for work to date for its sky blue quality, but a stronger blue was desired for these tests so 1% was chosen.

| Base D | No Colorant | Rutile | Talc | Chrome | Tin |

|---|---|---|---|---|---|

| No Colorant | G42-5 | ||||

| Rutile | T46-1 | ||||

| Talc | T46-2 | ||||

| Chrome | T47-1 | ||||

| Tin | T47-2 |

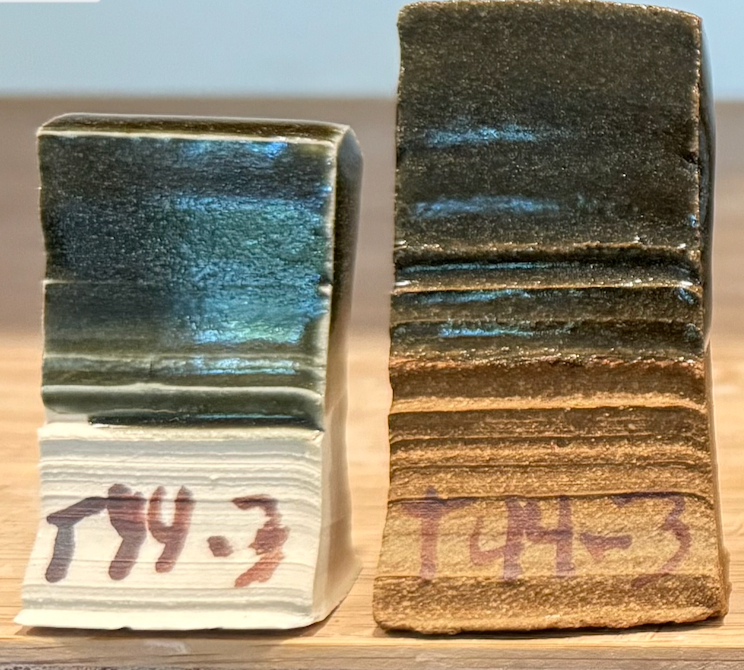

This is the result I was hoping for (above) with an interesting variegated blue starting at 3% and well developed at 4%, especially on the darker clay bodies. It's quite close to John Britt's, John's Cash Blue, which I use a lot, now in granite form. The 1% Cobalt Carbonate without Rutile (Tile 0) is also attractive.

Above is a closeup of the variegated blue at 4% Rutile. The clay body from left to right is B-Mix, Mt. Vision Sienna Red and Red Sedona.

Talc produced a variegated gold effect at 4%. It's a well developed glaze with an interesting pattern, but I am pretty sure I would not use it often.

Chrome (above) went straight to blah. Good to know.

Tin Oxide (above) produced a pleasant new glaze, especially in the 7.5%-10% range, providing a speckled glaze that feels deeper, almost 3D. Definitely promise here.

Two-Glaze Tests

Given the cobalt-based glazes presented above were already mixed, opportunity presented itself to perform a few more tests.

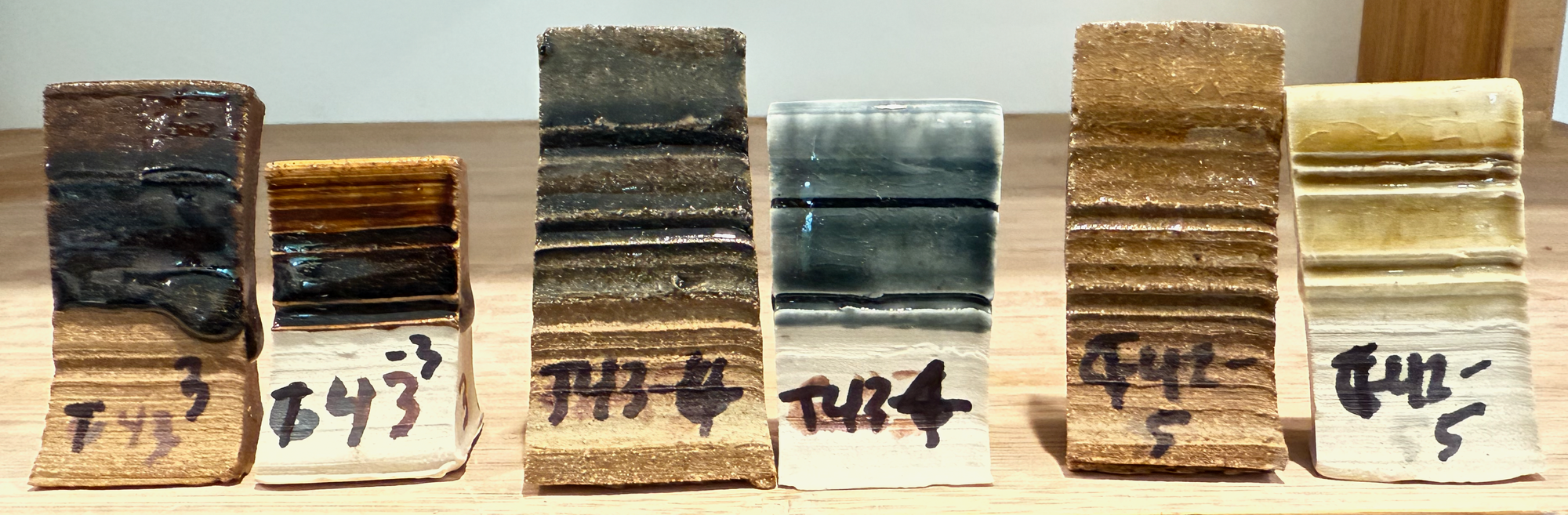

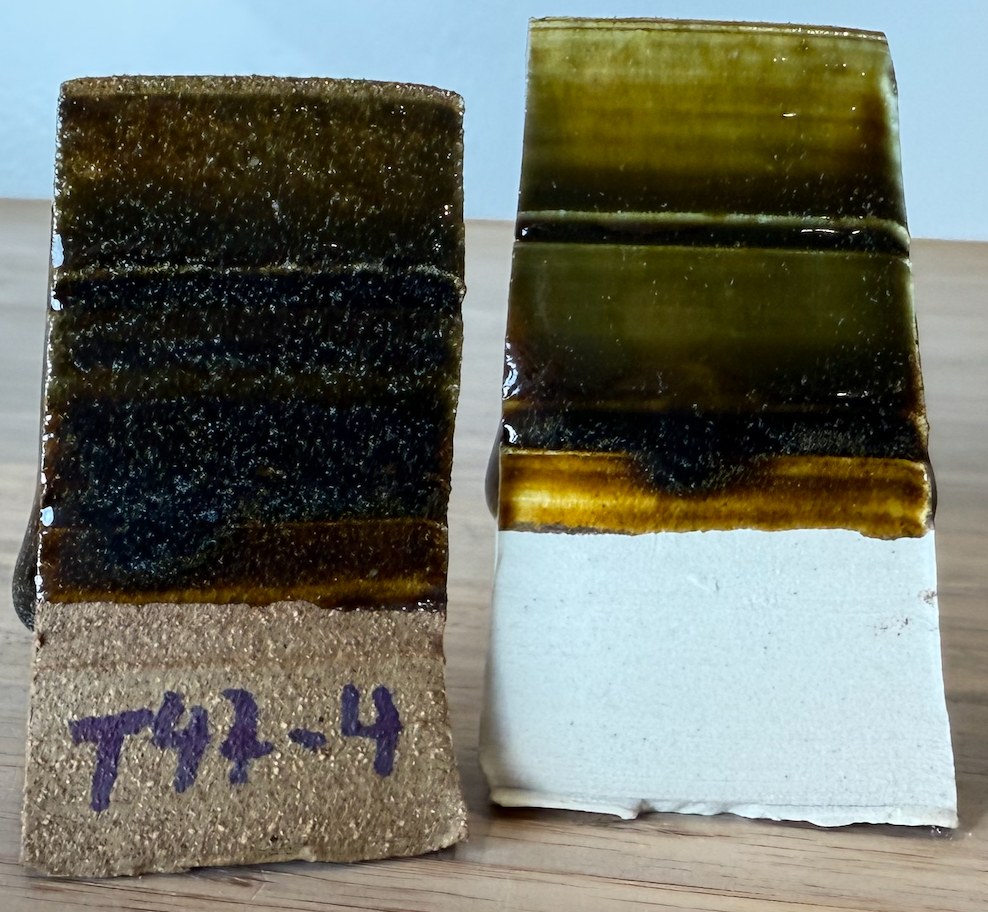

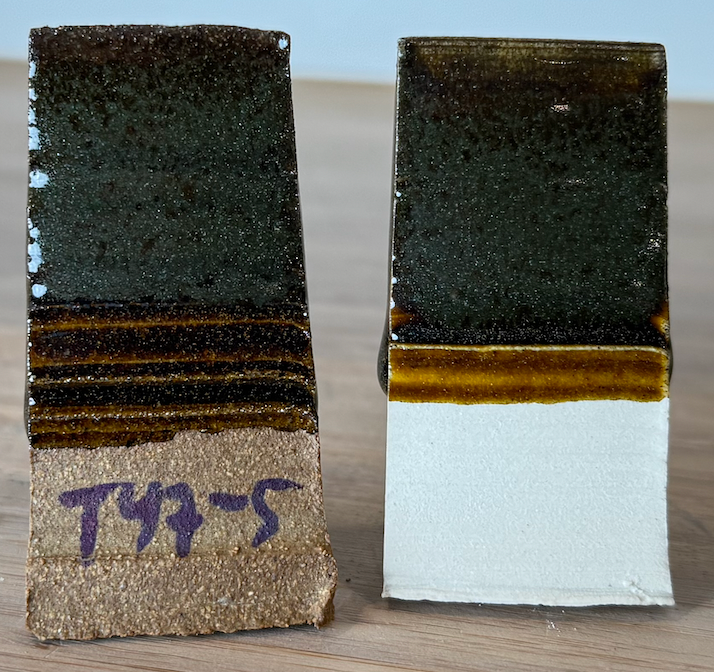

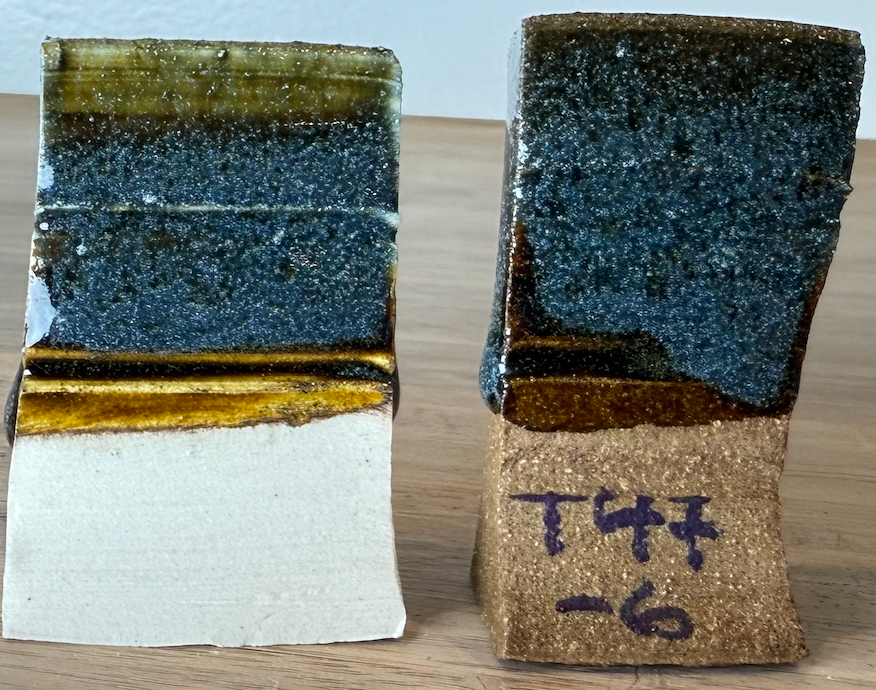

Below tests are presented using the Mt. Vision Tenmoku (T43-5: Base B (Silica version) + 10% Red Iron Oxide) as the undercoat and Base D (Base C (Zinc Oxide version) plus 1% Cobalt Carbonate), plus the named additive, as the overcoat.

| Undercoat | Overcoat | Result |

|---|---|---|

| Tenmoku (G43-5) | Rutile (T46-1) | T47-3 |

| Tenmoku (G43-5) | Talc (T46-2) | T47-4 |

| Tenmoku (G43-5) | Chrome (T47-1) | T47-5 |

| Tenmoku (G43-5) | Tin (T47-2) | T47-6 |

This looks very nearly like Mt. Vision Tenmoku under Britt's John's Cash Blue, which also uses Cobalt Carbonate and Rutile in similar proportions. This will be a useful glaze combination.

The Talc does not seem to add anything here, so punt or retest?

Much more interesting than T47-1 by itself. This could have some utility on the right piece.

This is good result as well. It has clear similarities and differences to the Rutile example and is a good candidate for further experimentation.

Notes

- Iron = Red Iron Oxide, Cobalt = Cobalt Carbonate, Tin = Tin Oxide, Chrome = Chromium Carbonate

- These tests used Granite Batch A, which is my first large batch.

- Most tests mixed 150 gm of material and added 150 ml water making a glaze with a specific gravity (SG) of ~1.5

- All tests fired to Cone 6 (30% Cone 7 by the cone)

- Test tiles are B-Mix (white) and Sedona Red (tan) and, where noted, Mt Vision Clay named Mt Vision Sienna Red

- Mixing Cobalt Carbonate and Red Iron Oxide moves from blue to green (see T44-2).