Mt Vision Granite - Iron Oxide

Description:

An iron oxide glaze was a first aim for the Mt. Vision Granodiorite and it is the most advanced glaze created thus far. It's a rich glaze, does not move much, nor craze, and the results are fairly stable across different batches of milled granite. Finer sieving and the addition of more silica have improved the results.

The granodiorite already possesses some iron in it naturally as discussed in the Base Glaze post found here.

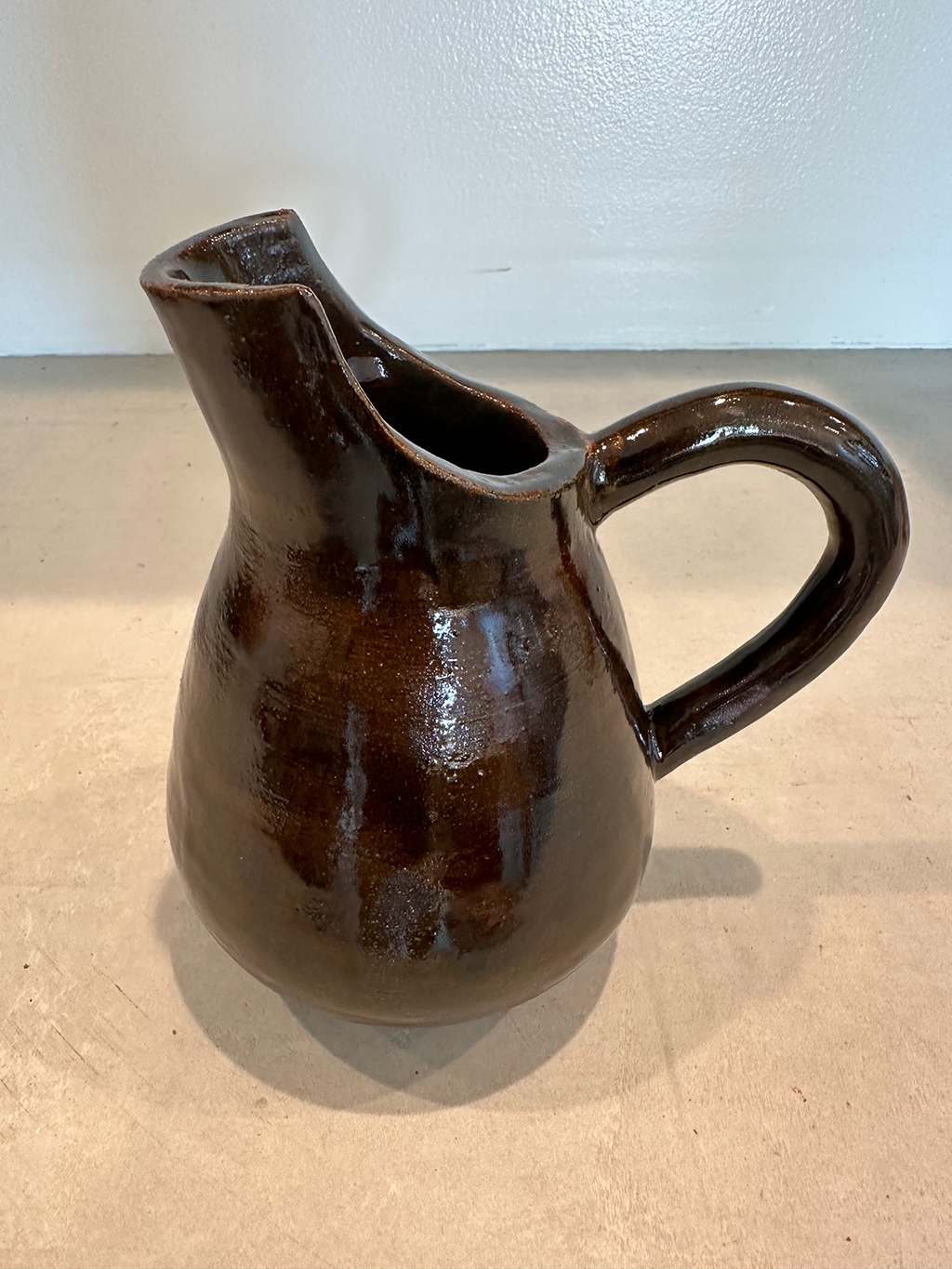

Mt Vision Tenmoku 10% Iron Oxide, SG ~1.42-1.43, the larger pieces are brushed 3x, otherwise poured

Glaze Recipe

Sieve at 80M, Specific Gravity (SG) 1.45 - 1.50

| Material | Amount |

|---|---|

| Mt Vision Granodiorite | 64% |

| Wollastonite | 27% |

| Silia | 9% |

| 100% | |

| Red Iron Oxide | 10% |

| Bentonite | 2% |

| 112% |

Firing

Kiln firing procedures are described here.

Tests

Test 10

Date:03/23/24

Type: Comparison of Test Tiles

Temp: Cone 6

Kiln: Test Kiln (T36), Main Kiln (G43)

Clay: B-Mix, Red Sedona

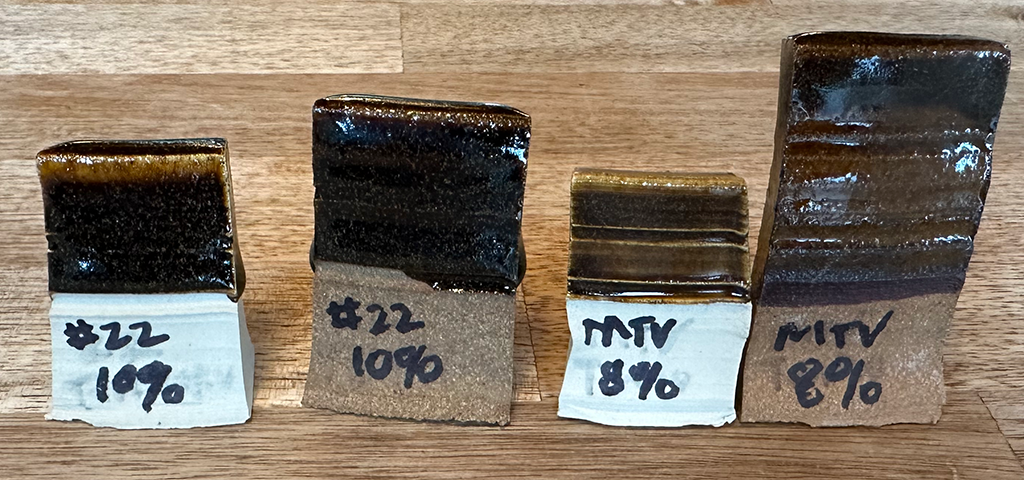

Method: Made a first large 3000g batch of Tenmoku, sieved to 60M and wanted to see what it would like sieved at 80M, SG 1.47.

I've been wondering if the larger particles that provide much of the variation in the glaze were also causing the glaze to run "dry" in places. And also, in some siutations, they can be too much.

The recipe is 64% MVG / 27% Wollastonite / 9% Silica + 10% Red Iron Oxide and 2% Bentonite which corresponds to Tile 3 in Test 9 below.

Notes

There is a decernable difference between the two batches that are difficult to see in the photo. While the 60M is fine, the 80M is defintely "cleaner", as expected, and has a more velvety texture, more glossy. This is an avenue worth persuing further.

Addendum: Tried 80M on large pieces and was very pleased with the results as they were comparibly more melted and silky with a bit more movement. No crazing. See the example below.

Test 9

Date:01/14/24

Type: Line Blend

Temp: Cone 6

Kiln: Test Kiln (T32)

Clay: B-Mix, Red Sedona

Method: Line blend to test variation of silica. Attempting to improve the consistency of the glaze and also compare the milled granite batches as the milling techniques are standardized.

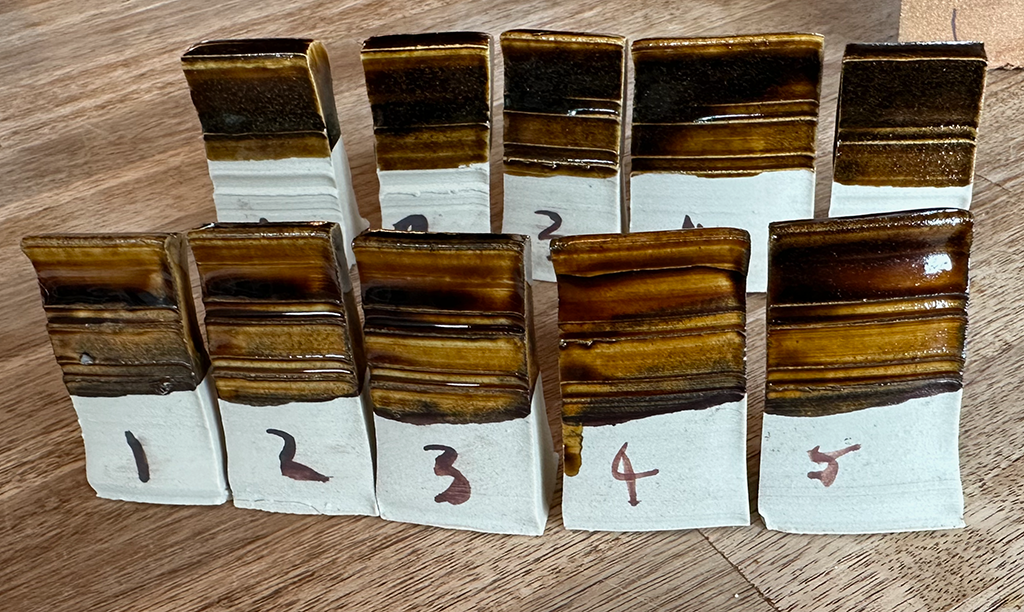

Cup A: 70% Granodiorite, 30% Wollastonite, 8% Iron Oxide

Cup B: Cup A + 20% Silica (normalized recipe before mixing)

Mixed 100gm of material in each cup with 125 ml of water.

Performed 2 tests, one with the original milled granite that mixed Granodiorite and Granite and the second with the latest milled granite that is just Granodiorite. They were so different visually I thought to test them (see photo below).

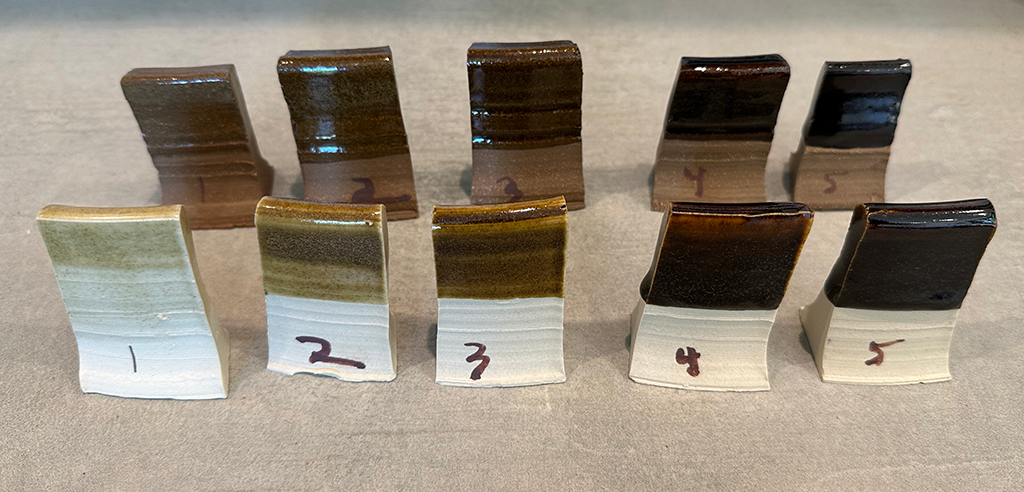

Back Row: Prior milled, mixed granite type, batch, Front Row: Latest milled, Granodiorite, batch (B-mix left and Sedona Red right)

Notes

- There was a small observable difference between the two granite mixes, but not so much chemically as consistency (this is good in the end).

- The addition of Silica did improve the glaze with tiles 3 and 4 the sweet spot (there really were no "bad" tiles). The newly milled granodiroite has an attractive silky quality.

Test 8

Date:01/04/24

Type: Test Tiles

Temp: Cone 6

Kiln: Test Kiln (T31)

Clay: B-Mix, Red Sedona

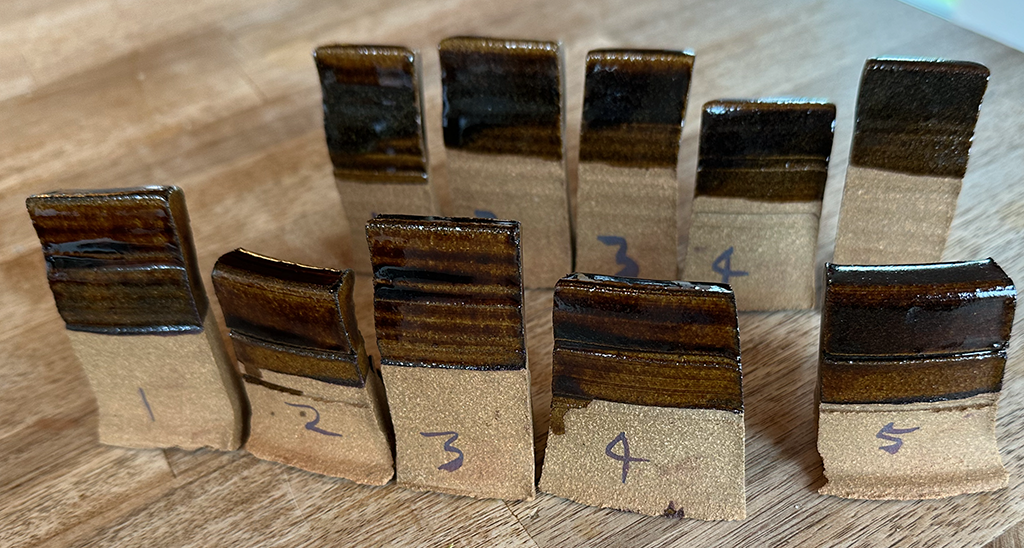

Method: A straight comparison of tile #22 in Test 7, 10% Iron Oxide, SG 1.47 compared to a batch of existing 70/30 - 8% Tenmoku (equivalent to tile #21 in Test 7).

The tile #22 formula is 67% Granodiorite, 29% Wollastonite, 4% Silica with 10% Iron Oxide and 2% Bentonite added.

Chemically this is a 1:10.3 aliumina / silca ratio with 0.77% Calcium and 0.18% K-Na

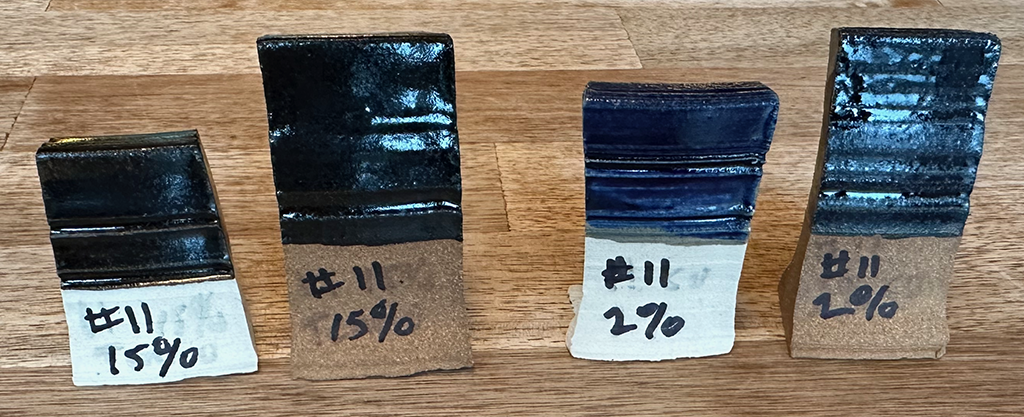

Also, for kicks, I refired the 15% tenmoku batch from Test 6, which simulated tile #11 from the Base Test 6. This was an alumina variation rather than a silica one.

Being in the test kiln this gives a chance to compare results in both kilns.

The addition of the Silca thickened the glaze, even at a lower SG, and it became a bit more runny. It didn't "thin out" like the original formulation.

While not 100% conclusive, it appears to be an improvement. This conclusion is supported by the parallell Base and Cobalt tests performed at the same time.

Also, the results are just like I've observed in the main kiln (and previously in the test kiln), though for the Tenmoku this has never been a concern like with the Base and Cobalt tests.

Finally it's worth noting the refire of the alumina enhancement test, which was not very satisfying in Test 6 below was more interesting this time (see the tiles above, left). A very interesting matte "black" was produced that is worth exploring.

Test 7

Date:12/25/23

Type: Biaxial 5x5 Blend Tests

Temp: Cone 6

Kiln: Main Kiln (G38)

Clay: B-Mix

Method: Each corner glaze contains 300 gm of material and 200 ml of water, making 300ml of solution. It was thick but I would not have wanted to add more than about 50ml more of water. The material stayed suspended fairly well.

The flux corner C is 70% Granite and 30% Wollastonite, the current base receipe. 20 gm of Silica was added to corners B and D and 15 gm of EPK (alumia) was added to corners A and B.

Oh boy, did I botch this one! But there is data to be gleaned. I meant to reduce the Silica and EPK to 10 grams each but an excel error thwarted me! And then I messed up mixing the samples and lost samples 12, 13, 14 and 17, 18, 19. Arg - the heart! No worries, we can continue.

The resulting corner recepies are

| A | B | C | D | |

|---|---|---|---|---|

| Granite | 183 | 156 | 210 | 174 |

| Wollastonite | 78 | 66 | 90 | 75 |

| Silica | 0 | 45 | 0 | 51 |

| EPK | 39 | 33 | 0 | 0 |

| 300 | 300 | 300 | 300 |

Then 8% of red iron oxide (24 grams) was added to each corner. I didn't measure the SG. I should have.

I applied the resulting blends to 1 5x5 flat tests and 1 set of 25 self standing test tiles.

The kiln was fired using the normal Kline Cone 6 ramp though I lowered the top temperature from 2215 to 2210 to inch the kiln back towards Cone 6 instead of being firmly past it. The upper portion of the kiln, where the test resided, fired to 30% Cone 7 with Cone 6 surpassed. At 2215 prior firings reached 35-40% Cone 7.

Tenmoku Test 7 Biaxial 8% Iron Oxide

Notes:

-

This time the 5x5 tile and standing test tiles collaborate with minor but notible differences.

-

Adding Silica seems to be more beneficial than adding Alumina, but I am missing six important tiles

-

In the Base glaze equivalent test it seemed adding Alumina was more beneficial than Silica, so I am surprised by these results. The difference between tests is the addition of Red Iron Oxide.

Very roughly this empirical mapping below can be gleaned from the tiles.

| A | underfired | underfired | underfired | underfired | matte | B |

| underfired | underfired | underfired | matte | glossy | ||

| underfired | n/a | n/a | n/a | matte | ||

| glossy | n/a | n/a | n/a | matte | ||

| C | glossy | glossy | glossy | glossy | glossy | D |

If we look at A, B, C and D in terms of their Silica to Alumina distributions we find

| A | B | C | D | |

|---|---|---|---|---|

| Silica | 3.09 | 3.97 | 2.80 | 3.68 |

| Alumina | 0.43 | 0.43 | 0.28 | 0.28 |

| Ratio | 1:7.2 | 1:9.2 | 1:10.0 | 1:13.1 |

If we extrapolate these numbers we get this approximate mapping with the most interesting tiles in bold.

| A | 1:7.4 | 1:7.9 | 1:8.4 | 1:8.9 | 1:9.3 | B |

| 1:8.1 | 1:8.6 | 1:9.2 | 1:9.7 | 1:10.3 | ||

| 1:8.7 | n/a | n/a | n/a | 1:11.2 | ||

| 1:9.4 | n/a | n/a | n/a | 1:12.2 | ||

| C | 1:10 | 1:10.8 | 1:11.6 | 1:12.4 | 1:13.2 | D |

So unlike the Base glaze equivalent test where the 1:8 tiles seemed to be an improvement over the 1:10 samples, here the 1:10 and higher samples seem to be the best.

Next steps:

-

Repeat to get full set of tiles, perhaps blow up the map by selecting 10 grams EPK instead of 15 and 15 grams Silica instead of 20.

-

Add a flux like Whiting or a non-calcium flux like Lithium. What I am calling glossy might be semi- or matte?!

-

Do a test with glaze 22,23 or 24 on some bigger pieces

-

A dolomite might be interesting to try as well

A final note, Corner C has produced a nice glaze so we are refining here.

Test 6

Date:12/14/23

Type: Line Blend

Temp: Cone 6

Kiln: Test Kiln (T30)

Clay: B-Mix, Sedona Red

Glaze: 66% Mt. Vision Granodiorite (60M seive) / 28% Wollastonite / 7% EPK + 2% Bendonite

Additive: Red Iron Oxide

Method: Iron Oxide 0%, 2%, 5%, 10% and 15% by adding 3, 4.5, 7.5 and 7.5 gm (cumulative 22.5 gm) without changing the amount of liquid, so the Specific Gravity (SG) rose as I went. 0% was 150 gm of material with 150ml water.

I forgot to measure the SG, but it was pretty watery and difficult to apply thickly.

This is a re-do of Test 1 with a different glaze formulation, namely test tile #11 in the base glaze test 6.

Also, I changed the way I mill the granite and this might be a cause of the watery glaze. It's visually not quite as fine even though it was passed through a 60M sieve. I will continue to research this.

Notes:

I had high hopes for this test since the base glaze biaxial test indicated the addition of the EPK would be an improvement to its quality - it did not.

One issue here is the glaze is too thin, with a lot of its particulant matter falling rapidly to the bottom, but the bigger issue is the glaze does not look fully melted!

One positive is the base glaze without colorant looks nice on the Sedona Red.

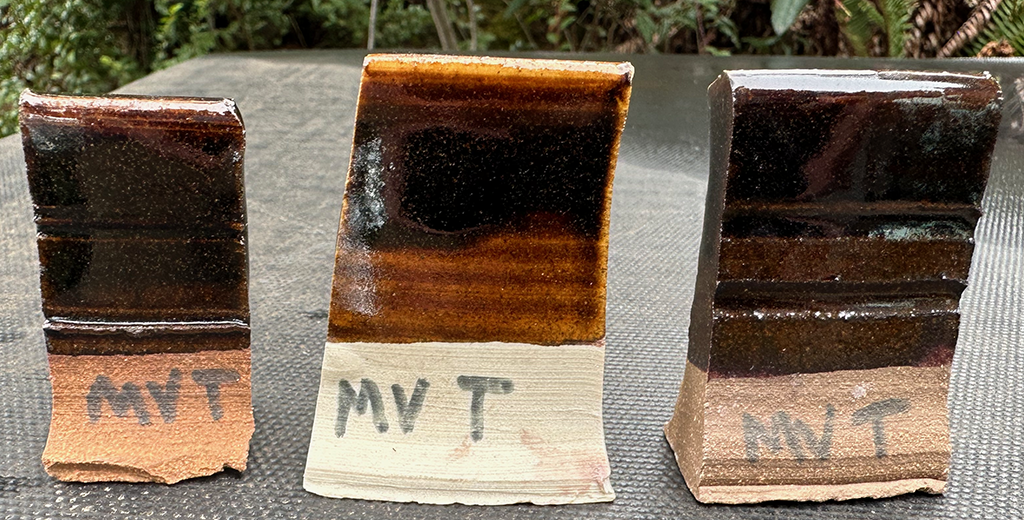

Test 5

Date:12/7/23

Type: Main Kiln

Temp: Cone 6

Kiln: Main Kiln (G37)

Clay: Porcelian

Glaze: 70% / 30% Mt. Vision Granite (12hrs milling / 60M seive) / Wollastonite

Additive: Red Iron Oxide 8%

Method: In an attempt to understand better why tests in the test kiln are glossy and tests in the main kiln are sometimes matt, all else being equal, this test places two equal pieces in separate places in the kiln (top (hot), bottom (cool)) to assess the affect, if any, this might have.

Note this problem is more manifest with the colbat tests than the iron oxide tests.

Notes

The recorded temperature difference was just 10% of a cone with the bottom of the kiln recording 25% cone 7 and the top 35% cone 7.

Each piece looks the same and so, in this case anyway, the temperature difference did not make any difference.

The glaze is glossy and semi-transparent/opaque and quite attractive. It needs to be applied thickly and is difficult to apply evenly.

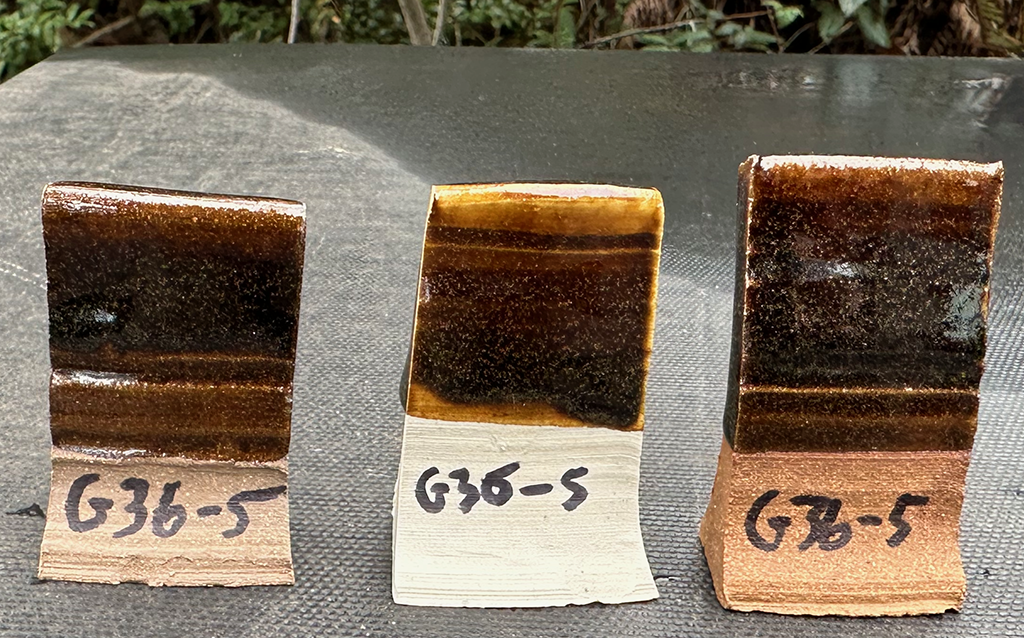

Test 4

Date:11/14/23

Type: Test Tiles

Temp: Cone 6

Kiln: Main Kiln (G36)

Clay: Sedona Red, Dark Red, B-Mix

Glaze: 70% / 30% Mt. Vision Granite (12hrs milling / 60M seive) / Wollastonite

Additive: Red Iron Oxide 8%

Notes:

This is one of the first tile tests performed in the main kiln. To date I've used the test kiln for these experiments and I've noticed small differences in outcomes over time, even though I've made some attempts to harmonize the two environments. For example, items sometines fire more matte in the main kiln than the equivallent tiles in the test kiln, but not always.

In this test I'm using the Mt Vision Tenmoku with 8% Red Iron Oxide and SG 1.50. I wanted to see what happened at the higher SG. I've also introduced a third clay body, Sedona Red.

Conclusions:

This is a good result. All three tiles are interesting, glossy and uncrazed. It's confirming a suspicion I've had for a while that a higher SG will produce better results, and lowing the iron content would compensate somewhat for the extra thickness. Also, the kilns are firing similarly, or so it appears in this case. In this firing, G36, the tiles were on the top shelf where Cone 6 was passed and Cone 7 was breached (the bottom of the kiln is always cooler).

See Tests 2 and 3 for a comparison.

Test 3

Date:09/11/23

Type: Test Tiles

Temp: Cone 6

Kiln: Main Kiln (T27)

Clay: Sedona Red, Dark Red, B-Mix

Glaze: 70% / 30% Mt. Vision Granite (12hrs milling / 60M seive) / Wollastonite

Additive: Red Iron Oxide 10%

Notes:

A quick test on all clay bodies at SG 1.43 in the Test Kiln (See Test 2 and 4 for a comparison).

Test 2

Date:09/04/23

Type: Test Tiles

Temp: Cone 6

Kiln: Main Kiln (G29)

Clay: Sedona Red, Dark Red, B-Mix

Glaze: 70% / 30% Mt. Vision Granite (12hrs milling / 60M seive) / Wollastonite

Additive: Red Iron Oxide 10%

Notes:

A quick test on all clay bodies with a higher SG 1.5 and in the main kiln (See Test 3 and 4 for a comparison).

Test 1

Date:8/06/23

Type: Line Blend

Temp: Cone 6

Kiln: Test Kiln (T25)

Clay: B-Mix, Dark Red

Glaze: 70% / 30% Mt. Vision Granite (12hrs milling / 60M seive) / Wollastonite

Additive: Red Iron Oxide

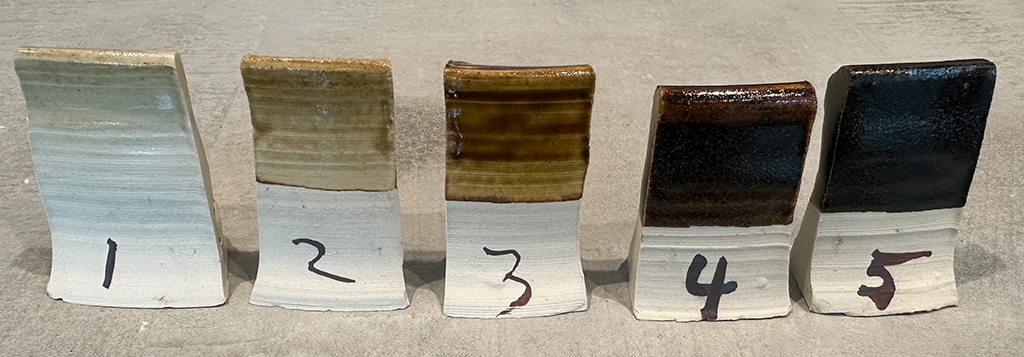

Method: Testing Iron Oxide 0%, 2%, 5%, 10% and 15% by adding 3, 4.5, 7.5 and 7.5 gm (cumulative 22.5 gm) without changing the amount of liquid, so the Specific Gravity (SG) rose as I went. 0% was 150 gm of material with 150ml of water giving an SG 1.50, so thick.

| MTV | |||||

|---|---|---|---|---|---|

| Red Iron Oxide | 1 | 2 | 3 | 4 | 5 |

| Added | +0g | +3g | +4.5 | +7.5g | +7.5g |

| Cumulative | +0g | +3g | +7.5g | +15g | +22.5g |

Notes:

A good test. Glaze looks good on both clay bodies. It’s melted and not crazed (much). 10% iron oxide was the most interesting, but they all warrant exploration. The base glaze (tile 1) is not clear and shows the iron that exists in the granite. The glaze has some interesting speckles that we see crop up elsewhere.